|

|

|

The hardware - back bed and engine |

The computers and major electronics boxes are located in the back bed area. The back bed tilts up, allowing access to the transmission and drivetrain underneath.

|

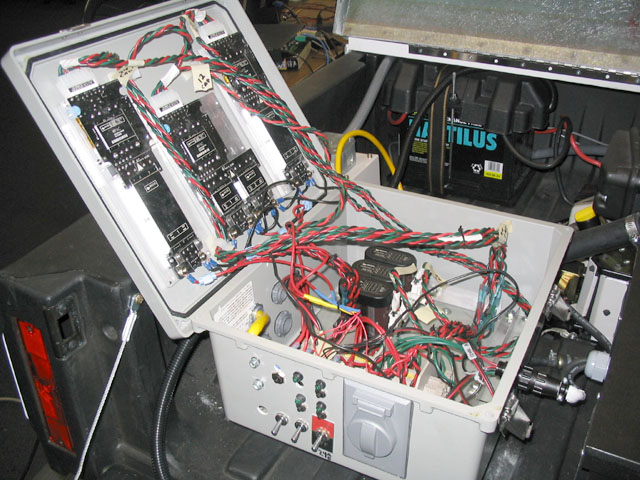

Overview of the back bed area. The back bed cover has been removed. The generator and power box are visible. The computer box was removed for servicing when this picture was taken. |

|

Overview of the back bed area. View from the rear, with the back bed cover in place but open. On the left is the grey power box. The black box on the right contains the main computers and some auxiliary equipment. Each box rests on shock mounts. Behind the power box, the auxiliary battery used to start the generator can be seen.

|

|

The back bed

is arranged so that opening the tailgate gives access to all necessary

controls and connections. |

|

|

The power box The four power supplies are in the lid, with large cooling fins projecting through the lid. (The fins can be seen in the overview picture above.) The two long power supplies at the ends each provide 24VDC at 20 amps each. The center unit provides two circuits of 12VDC at 20 amps each. All servomotors and controllers run on 24VDC, while most electronics runs on 12VDC. The power supplies are Vicor modular blocks.

|

| The switches turn on the 120VAC supply for the computers, the 12VDC supply for the electronics, and the 24VDC supply for the servos. Until the 24VDC supply is enabled, no actuator can move. Indicator lights and circuit breakers are provided above each switch. The open hole to the left of the switches will contain the generator start/stop switch. The convenience outlet provides 120VAC from the generator. | |

|

Computer box The blue box on the right is the top of a stack of Nova 8660 single-board industrial computer packaged and sold by Tri-M. The computer box provides space for a stack of three computers, but only two are installed. The gold box to the left of the computers is the Crossbow INS unit Above the INS unit are two CtrLink industrial Ethernet hubs. Between them, barely visible, is the small interface box for the VORAD radar. Terminal blocks at the left distribute 120VAC and 12VDC. |

| The panel on the front provides access to the vehicle's LAN and keyboard, serial, monitor, and mouse access to one of the computers. In practice, we tend to connect only to the Ethernet connection, which was plugged into the shop network here. We can use a wireless LAN during field testing, but the cable has more bandwidth. | |

|

Generator The Generac generator and its associated inverter provide 3KW of 120VAC at 60HZ. The generator's engine is fueled from the main fuel tank through a fuel pump, and exhausts out the bottom of the back bed. The generator actually generates 100VDC to 400 VDC, which is converted to a nominal 120VAC by the generator's inverter unit. |

| The generator is oversized for the application, but smaller portable generators use gravity feed for fuel and lack a fuel pump, which won't work in a moving vehicle. | |

|

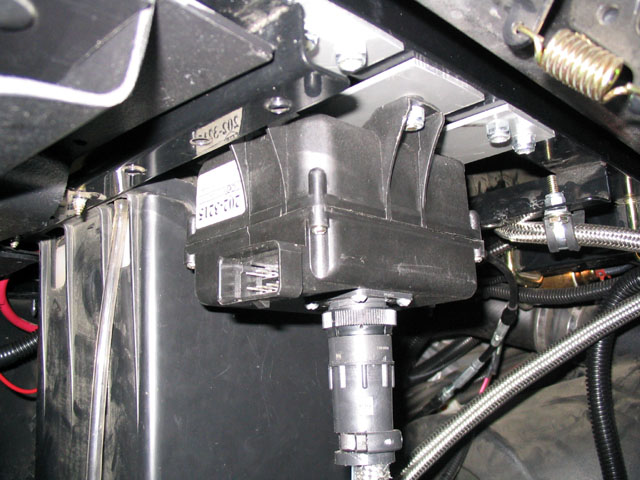

Throttle actuator A heavily modified cruise control unit undeneath the back bed operates the throttle. |

| The throttle actuator has a servomotor driving a leadscrew, which moves an electromagnet which in turn pulls on the throttle cable. The computers control the servomotor, but the electromagnet is controlled by the emergency stop system. If the electromagnet power is cut off, the engine drops to idle. | |

|

Main engine One cylinder, 30HP, driving a continouously variable transmission. The engine is located under the seat, with the attached transmission extending under the back bed. |

|

This vehicle is a bit underpowered. We like that; it's safer during testing. |